How do I adjust the panel size based on the edging thickness and the milling thickness?

RespondidaHello,

this is a very nice program, and i would like to buy it, but i have one main problem.

(and my english is very poor too)

but lets try...

example i have a board which is 200mm in width, which is my "end - width"

i have one edge at the right with 2mm.

my mill always takes 1mm away.

so if i want to display the correct board width it is like this

1mm(milling)+2(edge) so the board must be 199mm to get the end result of 200mm.

how do i config a paper edge which is like 0,3mm thick?

1mm(milling)+0,3(edge) board = 200,7

how do i config the edge in MaxCut to do this? is it possible?

could you help me please.

your help is much appreciated and regards from germany

christoph

-

Hi Christoph,

A partial answer to your question.

You asked:

How do i config a paper edge which is like 0,3mm thick?

1mm(milling)+0,3(edge) board = 200,7

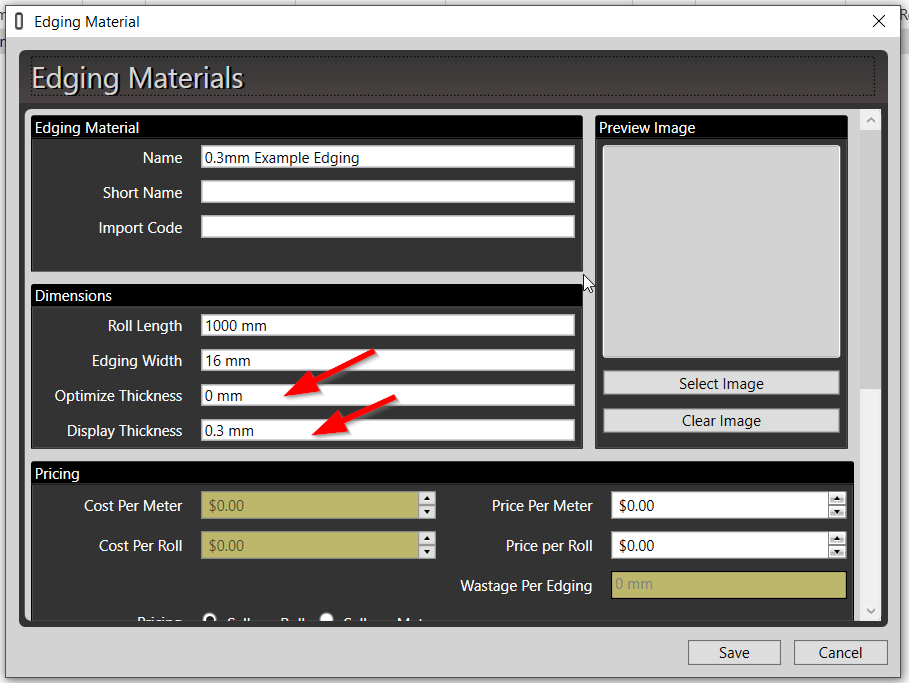

For paper edge where the thickness is a nominal 0.3mm thick you can set the display thickness and optimisation thickness to be different. In this case we would set the optimisation thickness to be 0 as in general it would not impact the end size.

To do this, go to:

Manage > Edging Materials

Select the edging you want to set and edit it. You will get an edging material display. Search for the optimize thickness and display thickness settings.

Set the optimize thickness to 0 and the display thickness to 0.3mm

On any of the diagrams it will show as 0.3mm thick however on the actual cutting it will not use a edging thickness.

We currently don't have a way to specify the mill thickness on an input panel. We have a blade thickness that is used to calculate the gap between panels but nothing that would impact a cuttting gap on a panel.

Could you explain further what you mean by a mill thickness?

0

Por favor, entrar para comentar.

Comentários

1 comentário